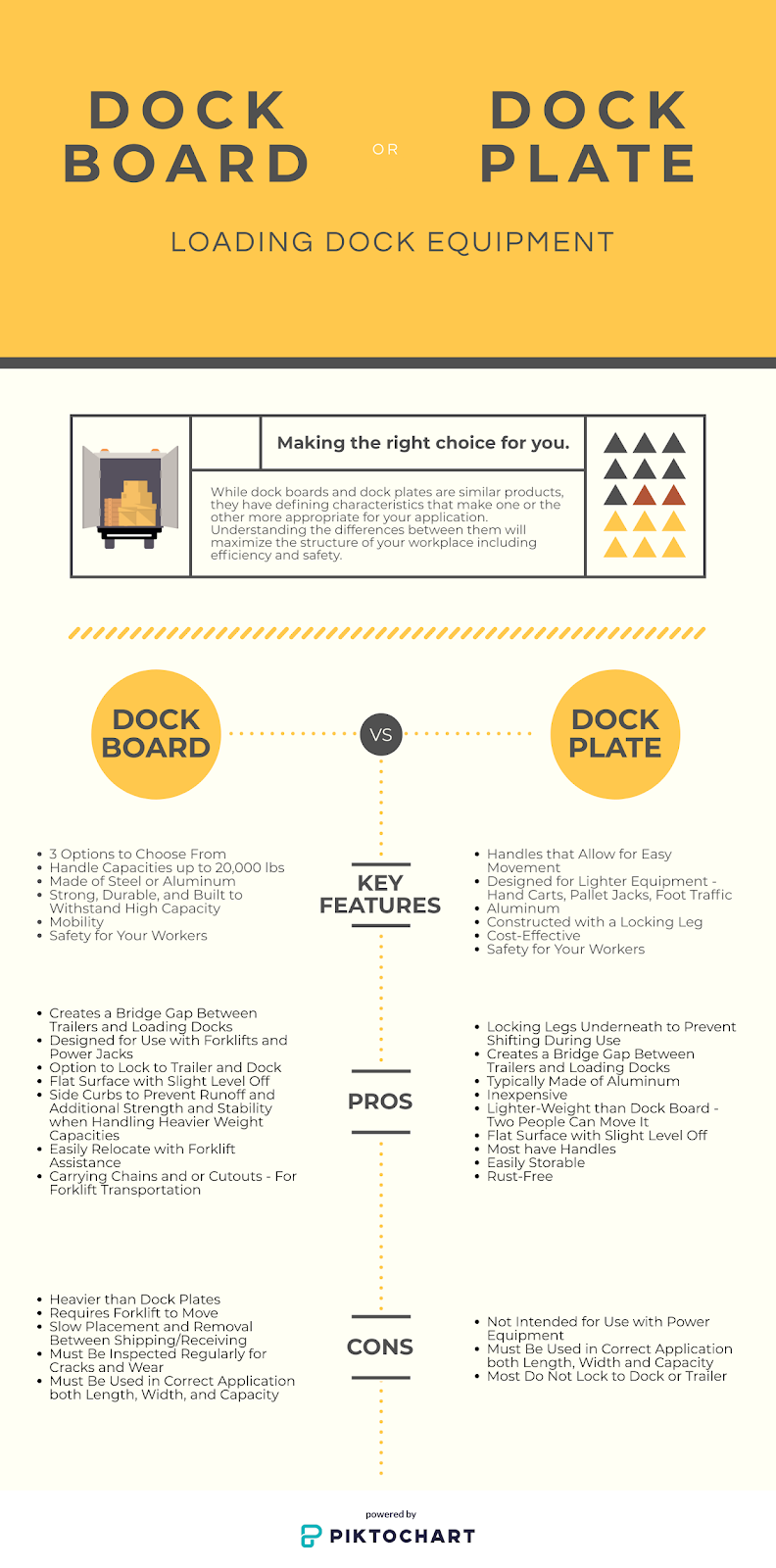

Dock Board or Dock Plate. Making the right choice for you.

While dock boards and dock plates are similar products, they have defining characteristics that make one or the other more appropriate for your application. Understanding the differences between them will maximize the structure of your workplace including efficiency and safety. Though very similar in appearance and function knowing the differences allows you to choose which one best fits your application needs.

Dock boards provide loading and unloading capabilities in heavy-duty applications and bridge any gaps that present any safety concern. They offer ease when using forklifts and other material handling equipment. Copperloy’s dock boards come in steel with welded curbs, aluminum with bolt-on steel curbs, and aluminum with welded curbs. Copperloy’s dock boards can be customized to match any specification, solve difficult challenges, or work with preexisting equipment or spaces.

Dock plates are very much like dock boards but do not have curbs. These are used to bridge a gap from one area to another in material handling operations. However, unlike dock boards, dock plates are a flat piece of metal with a slight bend for an easy transition. Dock plates come in either steel or aluminum and can reach capacities up to 17,000 pounds. Interestingly, the extra capacity that dock boards are able to achieve comes from the structural addition of curbs.

So when it comes down to dock board vs dock plate you need to consider what will you be using your dock equipment for?

Comments

Post a Comment